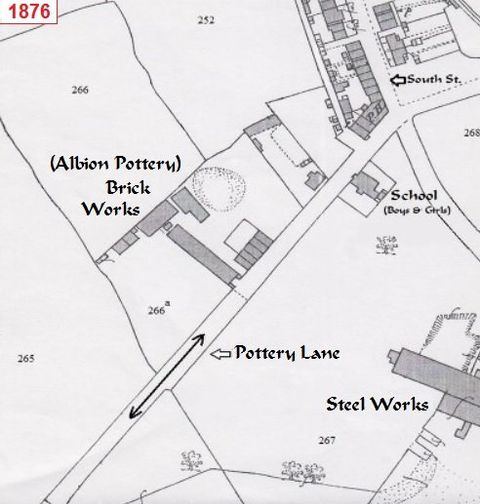

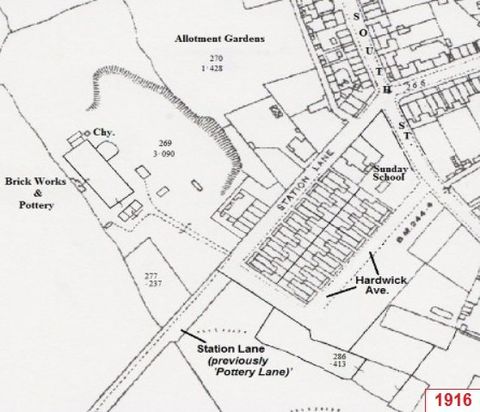

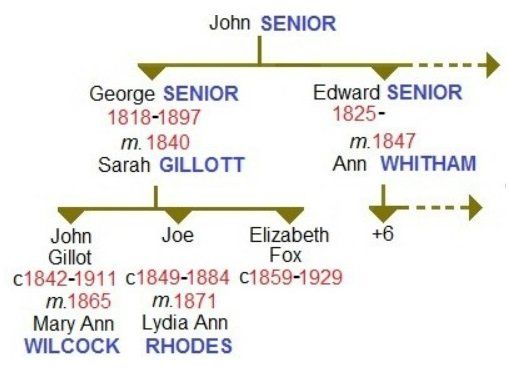

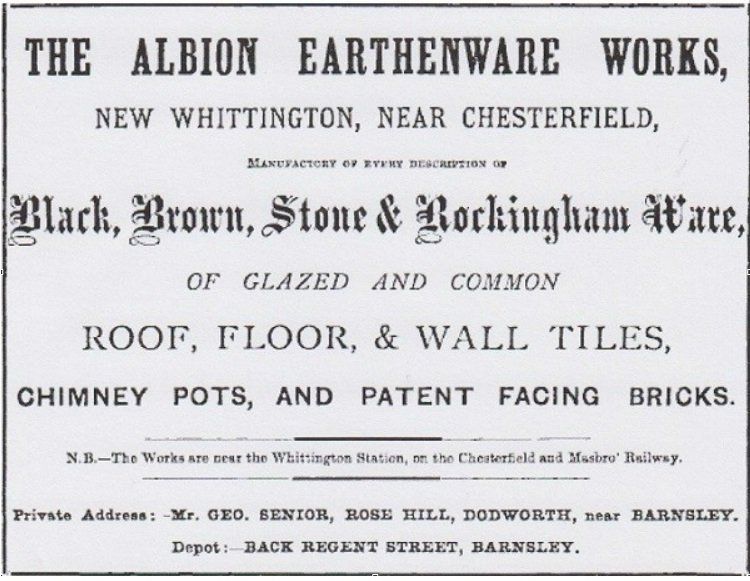

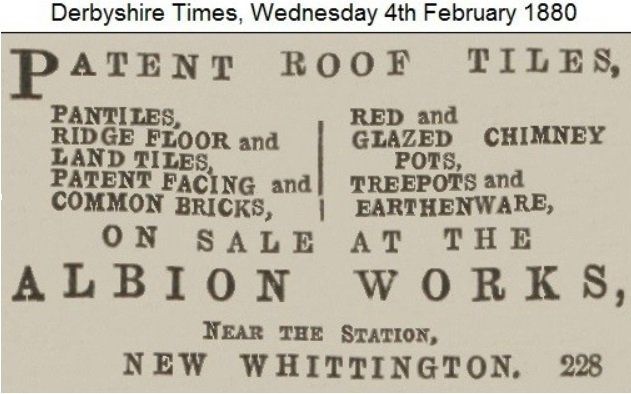

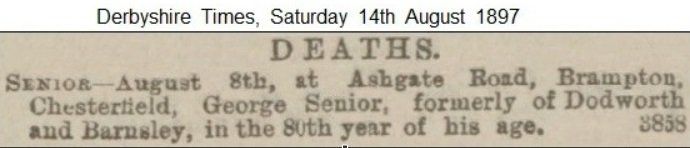

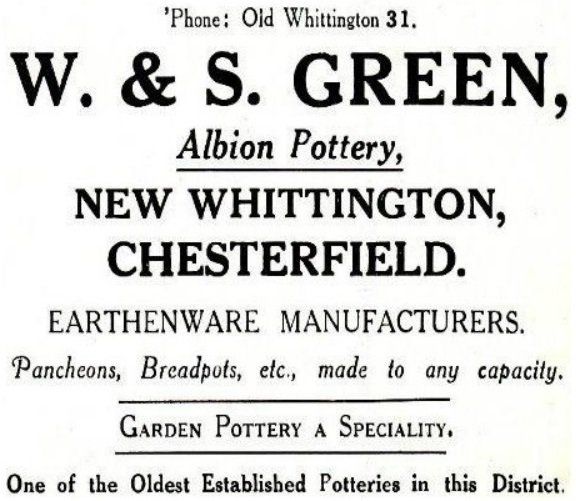

The Pottery was established c1876, next to the Brick Works, by George Senior, who also owned the brickworks.

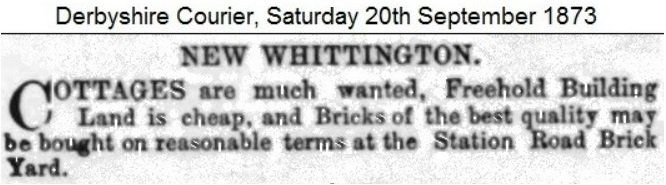

The earliest reports I've found are for the brick works.

George Senior decided to build the Albion Pottery.

The Derbyshire Courier, Saturday 6th June 1874

"TENDERS WANTED for a THIRD YARD CHIMNEY, and a seven-chambered BRICK KILN - for plans and specifications, apply at the Station Road Brickworks, Whittington, Chesterfield.

And to be Sold, a Seven Feet CLAYMILL, of the very best construction. It may be seen daily at the aforesaid Brickworks."